ALL ABOUT EXPERIMENTAL MACHINE & TOOL CO. LLC

Precision, Experience, and Agility

In 1952, Experimental Machine & Tool Co. was started as a small tool and die shop servicing the greater NYC metro. Due to the ingenuity and hard work of its founder and family members, the business grew rapidly leaving its mark on millions of parts manufactured on tooling produced by the company. In the 1980's due to changes in the market, the first CNC Machine Tools were purchased establishing Experimental Machine & Tool as one of the premier CNC machine shops in Central New Jersey. The company is under second generation leadership, continuing to grow in technology and capabilities in the 21st Century.

CAPABILITIES

Meeting Your Machined Parts Needs from Prototype through Production

With over 25 pieces of high quality subtractive manufacturing equipment, Experimental Machine & Tool can handle almost any job from 1 piece to 1,000's per year in our fully climate controlled facility

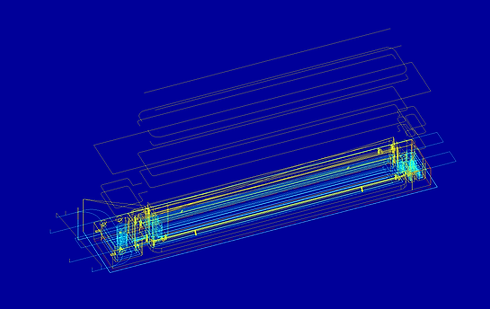

DIGITAL MANUFACTURING

Attention to Detail from the Start

Utilizing the latest CAD/CAM, we consider all project requirements from RFQ through production enabling robust process planning. We accept .stp files as a standard. Benefits include:

Faster pace of innovation

Project Lead Time Reduction

Process Agility and Adaptability

Lowered Cost of production

- Quality Ensured

DFM (Design for Manufacturability) feedback

RAPID PROTOTYPING

Taking Concepts to Reality

Diverse capabilities ensure rapid prototyping through multiple subtractive manufacturing methods. Faster prototyping allows the best iteration to be production ready faster. All prototyping is easily scalable to full production in house due to diverse production capability, scalable capacity, and large network of Supply Chain Strategic partners.

CONVENTIONAL MACHINING

Always Prepared

A large mix of conventional machining equipment ready for any job:

Horizontal Boring Mill with 48"x48" rotary table and steady rest

Multiple Hardinge High Precision chuckers

Multiple Bridgeport Vertical Mills

Multiple Leblond Flatbed lathes up to 20" Diameter and 40" long (with steady rest)

Vertical Bandsaws

Other support equipment

CNC MACHINING

High Production Ready

2 CNC Vertical Machining Centers up to 30"x16"x18" travels

4 CNC Horizontal Lathes up to 20" swing, 30" part length, (one w/ live tooling and sub spindle)

1 Fully Automatic Production Horizontal Band Saw

Other support equipment

GRINDING

Part Precision Guaranteed

Inhouse Rotary Surface Grinding (Blanchard), Peripheral Surface Grinding, and ID Honing allow for full control over part precision and lead time.

OUTSIDE SERVICES

One Stop Shop

The following are some of the additional value added services we can offer through our Supply Chain Network of Strategic Partners:

Heat Treatment

Anodizing

Plating/Painting/Other Coatings

Wire EDM

OD Grinding

Gun Drilling

Gear Cutting and Broaching